Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

Solutions and Applications

Medical Technology

Precision Manufacturing

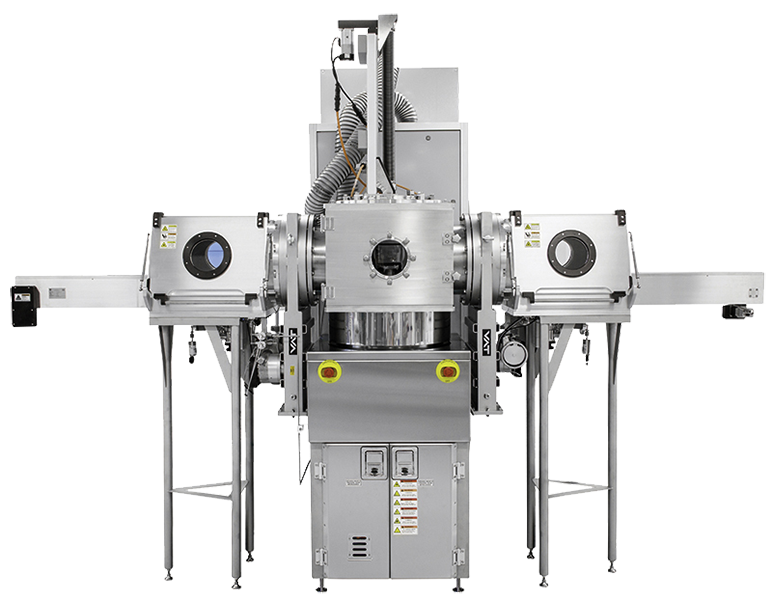

Applied™ Picosun™ P-300BV

Applied™ Picosun™ P-300BV ALD system is specially designed for production of LEDs, discrete devices, and MEMS devices such as print heads, sensors, and microphones.

By integrating our hot-wall design with fully separated inlets, we can create the highest quality ALD films with excellent yield, low particle levels, and superior electrical and optical performance. The agile design with easy and fast maintenance ensures minimum system downtime and lowest cost-of-ownership in the market. Picoflow™ diffusion enhancer technology enables highly conformal coatings on ultra-high aspect ratio substrates with production-proven processes.

Applied™ Picosun™ P-300BV ALD system represents the cutting-edge of industrial ALD. The system is designed for semi-automated handling of wafer batches. The tool is optimized for fast batch production. Vacuum loading system enables clean processing of sensitive substrates and deposition of materials such as metal nitrides.

Typical Substrate Size and Type

- 200 mm wafers in batches of 25 pcs (standard pitch)

- 150 mm wafers in batches of 50 pcs (standard pitch)

- 100 mm wafers in batches of 75 pcs (standard pitch)

- 100 mm wafers in batches of 100 pcs (standard pitch)

- Non-wafer substrates (tailored holders)

- High aspect ratio samples (up to 1:2500)

Processing Temperature

- 50 – 450°C

Typical Processes

- Batch processes available with cycle times down to single digit seconds

- Al2O3, SiO2, Ta2O5, HfO2, ZnO, TiO2, ZrO2, AlN, TiN, and metals

- Down to <1% 1σ non-uniformity in a batch (Al2O3, WIW, WTW, B2B, 49 pts, 5mm EE)

Substrate Loading

- Semi-automatic loading with vertical loaders (one or two loaders)

Precursors

- Liquid, solid, gas, ozone

- Level sensors, cleaning and refill service

- Up to 7 sources with 4 separate inlets